High-Precision Enzyme Dispensing Machine for Glucose Test Strips

- China

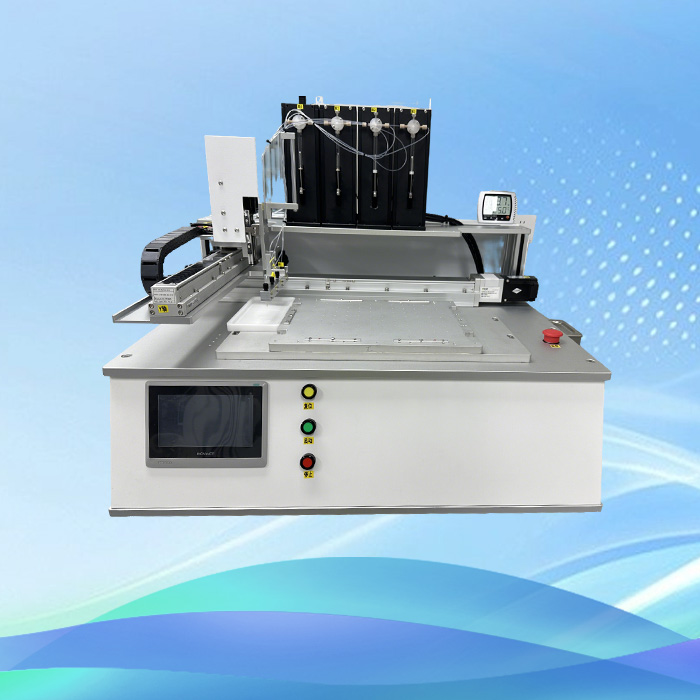

Semi-Automated high-precision enzyme dispensing machine for glucose test strip manufacturing. Accurate, fast, and reliable non-contact dispensing system.

Our Enzyme Dispensing Machine is designed for high-precision application of enzyme solutions onto glucose test strips, biosensors, and other diagnostic devices. Equipped with advanced non-contact jetting technology and semi-automated control, it ensures consistent spot volume, precise positioning, and high production efficiency — making it the ideal choice for modern medical diagnostic strip manufacturing.

Core Features

CCD Automatic Positioning Technology

Precisely identifies sample positions to ensure testing accuracy and repeatability, eliminating the impact of human error.

Dual-Servo Dispensing Pump Design

The plunger pump execution system adopts a dual-servo independent control architecture, improving liquid dispensing efficiency and stability while ensuring uniformity in dispensing volume.

Piezoelectric Valve Control System

Faster response and more precise control guarantee uniform liquid output, addressing common issues in non-contact dispensing such as droplet hanging and splashing.

Ultra-Micro Dispensing with Exceptional Precision Control

Supports a minimum dispensing volume of 0.1 μL with a CV value of less than 3%, meeting the needs of micro-volume and high-precision testing applications.

Automatic Needle Lifting & Multi-Height Dispensing Coordinates

Equipped with automatic needle lifting, the system allows independent dispensing height settings for each spot. Supports flexible configurations such as linear, circular, and array patterns to meet complex sample dispensing requirements.

Flexible Dispensing Modes

Easily switch between:

• Single spot

• Line drawing

• Line spraying

• Single-spot spraying

Enabling customized dispensing processes for maximum application adaptability.Large Working Area

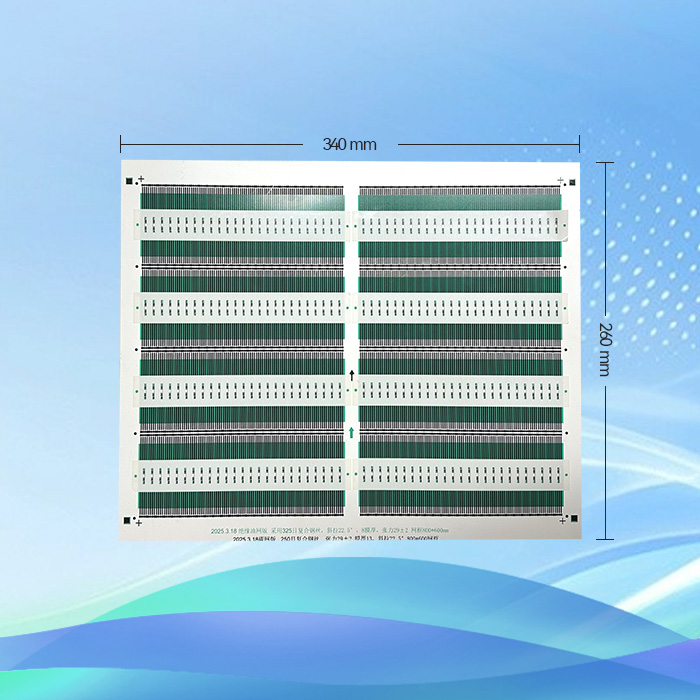

Standard travel is 500 × 350 mm, with maximum support for a 600 × 600 mm working area to accommodate medium- to large-scale laboratory high-throughput requirements.

Multi-Channel Expansion Design

Pre-reserved expansion slots allow flexible addition of dispensing channels, ensuring easy maintenance and scalability for future needs.

Technical Specifications

Model | WM-403 |

Worktable Travel Range | 100mm ~ 600mm (Customizable based on product size) |

Positioning Error | ±0.02mm |

Full-Stroke Accuracy | <2% |

Full-Stroke Precision | ≤1% |

Back-Suction Unit | Optional |

Cleaning Function | Automatic self-cleaning |

Syringe Volume | 50μL ~ 1mL |

Standard Dispensing/Aspiration Resolution | 24000 steps |

Microstep Dispensing/Aspiration Resolution | 48000 steps |

Precision | <1% |

Accuracy | <2% |

Dispensing Volume | 50nL~1μL |

Number of Channels | 1 ~ 16 |

Channel Settings | Independent volume control per channel |

Dispensing Speed | 2-100 times/sec (Depends on value/pump type) |

Axis Travel Speed | Up to 15m/min |

Control System | Motion controller |

CCD Positioning | Optional add-on |

Programming & Operation | Touchscreen HMI |

Dimensions | 760mm x 550mm x 600mm (May vary with travel range ) |

Power Supply | 220V 50/60Hz, 1.7KW |

Air Supply Requirement | 0.6 ~ 0.8MPa (Optional) |

Machine Weight | Approx. 90kg |