How to Start a Blood Glucose Meter Production Line with SKD Kits

Starting a blood glucose meter production line is a strategic move for medical device manufacturers aiming to meet growing demand in diabetes care. Using SKD glucose meter kits, you can quickly set up a cost-effective and scalable local assembly operation.

In this article, we will explain how to launch your own blood glucose meter production line using high-quality SKD glucose meter kits, reducing costs and accelerating time to market.

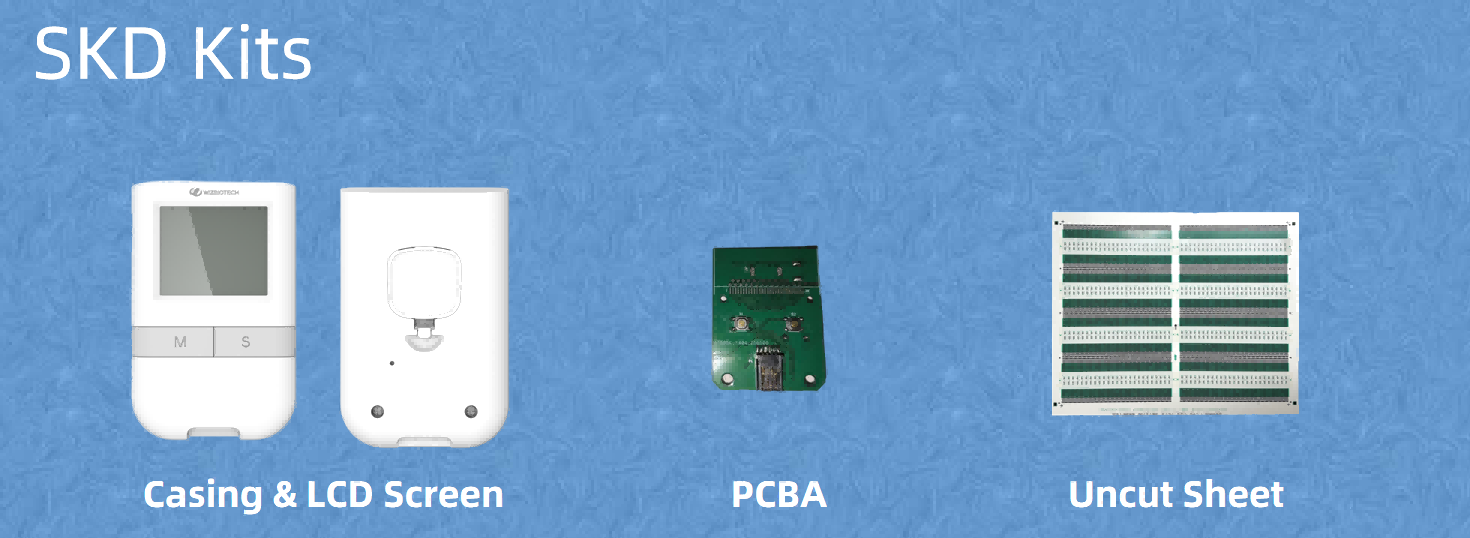

What Are SKD Glucose Meter Kits?

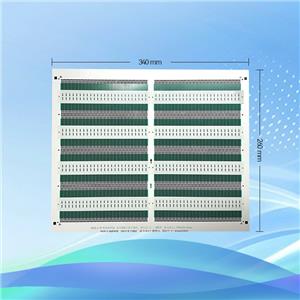

SKD glucose meter kits are packages containing semi-assembled components essential for building a reliable blood glucose test system. These kits include calibrated PCBAs, housing parts, Segment LCD screens, and electrochemical test strips uncut sheet.

Using SKD glucose meter kits allows manufacturers to import parts at lower tariffs and assemble the final blood glucose meter locally, establishing a flexible and branded blood glucose meter production line.

Step-by-Step Setup for Your Blood Glucose Meter Production Line

1. Define Your Production Volume

To start your blood glucose meter production line, estimate how many meters you want to produce monthly. This determines your inventory of SKD glucose meter kits and the scale of your assembly process.

Small production lines can rely on manual assembly of SKD glucose meter kits, while larger lines may invest in semi-automatic machinery to increase throughput.

2. Select the Right SKD Glucose Meter Kits Supplier

Choosing a reliable supplier of SKD glucose meter kits is critical for quality and compliance. Look for suppliers providing ISO-certified components, assembly manuals, and technical support for your blood glucose meter production line.

Good suppliers will customize SKD glucose meter kits to match your brand requirements, making your local production more efficient.

3. Prepare Your Assembly Facility

Your blood glucose meter production line should have clean, static-free areas with proper tools to assemble SKD glucose meter kits. This includes workstations for PCB installation, housing assembly, and functional testing.

Depending on your investment, you can use automated testers or manual test setups to verify assembled meters from SKD glucose meter kits.

4. Train Your Assembly Team

Workers on your blood glucose meter production line need training to correctly assemble components from SKD glucose meter kits, perform quality checks, and package the final product.

Training provided by your SKD glucose meter kits supplier can reduce errors and speed up assembly.

5. Brand and Distribute Your Blood Glucose Meters

Once assembled, your blood glucose meter production line will produce branded meters ready for distribution. Use supplier documentation to register your meters locally and start marketing your new blood glucose meter brand.

Why Choose SKD Kits for Your Production Line?

Compared finished products, building a blood glucose meter production line using SKD glucose meter kits reduces costs and allows faster market entry, especially for those localized preferred countries. This approach offers:

Lower import tariffs

Flexibility in customization

Full brand control

Scalable production setup

If you want to launch a scalable and flexible blood glucose meter production line, SKD glucose meter kits are your ideal starting point. Contact us today to learn how our SKD glucose meter kits can help you produce high-quality meters locally and grow your brand.