How Smart Temperature Monitoring Reduces Lab Operational Costs

In today's research landscape, laboratories are expected to operate at the highest standards of precision, compliance, and efficiency. While many institutions focus on acquiring advanced analytical equipment and hiring top-tier scientific talent, a surprisingly significant source of operational inefficiency is often overlooked: temperature monitoring. Temperature-sensitive environments, such as cold storage units, incubators, and reagent rooms, are vital to everyday lab work. Yet in many labs, the management of these conditions remains outdated, manual, and costly in more ways than one.

Traditionally, lab technicians or assistants are assigned to record temperatures manually throughout the day. These handwritten logs are then stored in binders or spreadsheets, requiring regular upkeep, review, and auditing. This process consumes valuable human resources, especially in institutions where staff already juggle multiple responsibilities. Beyond being inefficient, manual logging opens the door to human error—missed recordings, misread thermometers, or illegible entries that compromise both data integrity and regulatory compliance. The labor cost associated with this outdated routine is often hidden, but cumulative. Over the course of a year, it represents dozens, if not hundreds, of hours that could have been redirected toward meaningful scientific work or facility improvement.

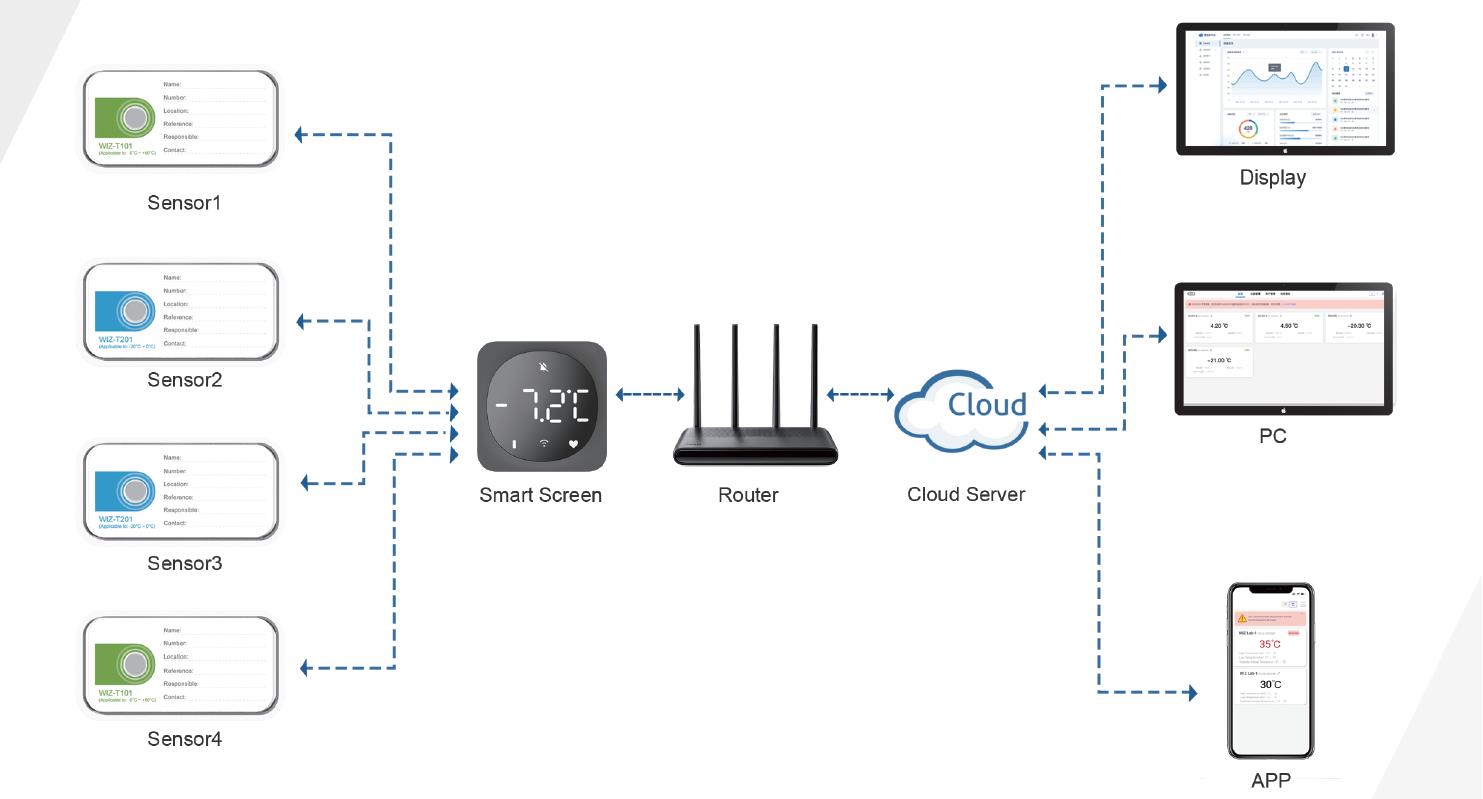

The introduction of a smart temperature monitoring system completely changes this dynamic. By deploying compact wireless sensors connected to a smart screen and cloud-based management platform, laboratories can automatically record environmental data around the clock. This real-time data is instantly available from any location through a mobile device or web interface, eliminating the need for on-site checks. Instead of walking from freezer to freezer, staff can now view the entire facility's temperature status at a glance. Temperature reports can be generated with a few clicks, including historical data that is timestamped, securely stored, and audit-ready.

But the benefits extend far beyond saving time. One of the most costly risks in any laboratory is temperature failure—when a freezer door is left slightly ajar, when an incubator malfunctions overnight, or when a power outage goes unnoticed. The financial and research impact of lost samples, degraded reagents, or spoiled experimental materials can be devastating. Smart systems offer peace of mind through real-time alerts that notify managers instantly via email, or app if any abnormal temperature conditions are detected. These early warnings allow staff to respond before significant damage occurs. In high-stakes environments such as pharmaceutical research or molecular biology labs, that few minutes' head start can prevent the loss of weeks or months of work.

Another often unrecognized source of operational cost lies in energy usage. Environmental control equipment runs continuously, often without performance optimization. Smart systems collect temperature trend data over time, revealing patterns that suggest inefficient usage—such as overcooling during off-hours or unnecessary fluctuations caused by equipment cycling. With access to this data, lab managers can make informed decisions about adjusting thermostats, upgrading insulation, or scheduling maintenance more effectively. Over time, these incremental adjustments result in real, measurable savings on utility bills without compromising environmental stability.

Regulatory compliance is yet another area where smart monitoring proves invaluable. Labs operating under GLP, GMP, or ISO standards must demonstrate strict adherence to environmental controls, which includes meticulous recordkeeping. Manual logs often fall short during audits due to missing data or lack of timestamp verification. Automated systems ensure that every reading is digitally recorded, unalterable, and easily traceable, significantly reducing the burden of audit preparation. Some laboratories report up to a 70% decrease in documentation time and a much smoother inspection process simply by switching to automated monitoring.

What truly sets modern temperature systems apart is their adaptability. Whether overseeing a single facility or coordinating multiple labs across cities or campuses, these systems are inherently scalable. New sensors can be added effortlessly, and permissions can be assigned to various team members according to their roles. The centralized dashboard gives a complete overview of temperature performance across all units and locations, enabling proactive management and fostering cross-site consistency. As remote work and hybrid models become increasingly common, the ability to access and manage critical lab data from any location has shifted from a luxury to a necessity.

While a smart temperature monitoring system may appear at first to be a technological upgrade, it is more accurately a long-term operational strategy. It addresses multiple cost centers simultaneously—labor, energy, materials, compliance—and does so with minimal disruption to existing workflows. The savings are both tangible and strategic, improving not only the day-to-day functioning of the lab but also its resilience, scalability, and readiness for future growth.